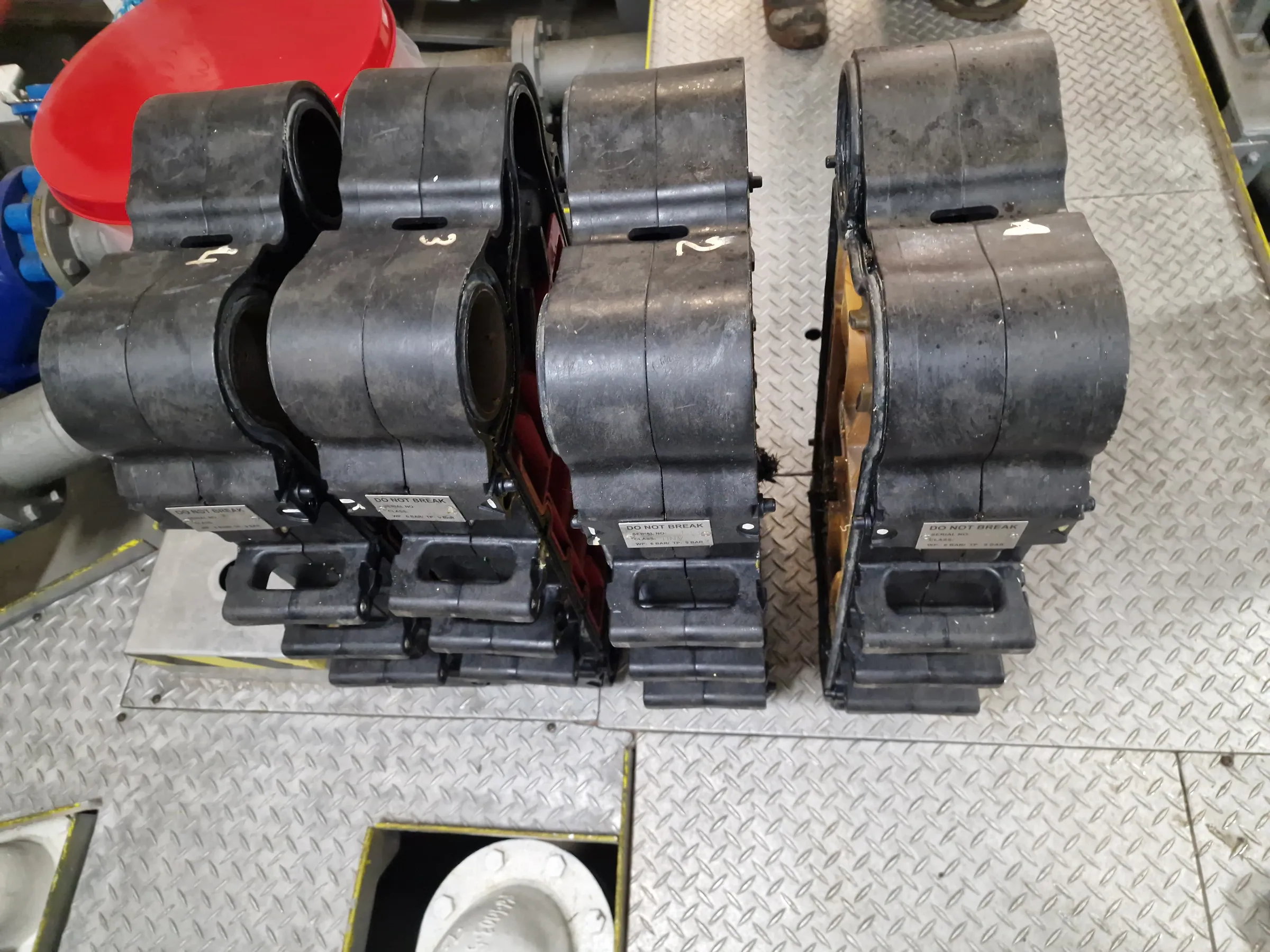

Plate Heat Exchangers (PHE)

Plate Heat Exchangers (PHE)

Nordic Green Products provides comprehensive cleaning services using the specially formulated cleaning agent NGP Valhall Fluid, ensuring optimal performance and extended operational lifespan of your heat exchanger systems.

- Evaluate fouling type and severity.

- Select appropriate method tailored to specific fouling conditions.

- Safely disassemble the PHE.

Inspect plates and gaskets for wear or damage.

- Perform chemical cleaning with NGP Valhall Fluid, a professional-grade, biodegradable cleaning solution designed specifically to remove:

- Rust and oxides

- Mineral scale (lime)

- Salts

- Algae and biological deposits

- Rust and oxides

Valhall Fluid is formulated with mild acids, providing a powerful yet safe cleaning action. It effectively dissolves deposits without damaging metal surfaces or components, although caution is required as it may corrode galvanized or zinc-treated surfaces.

- Following chemical treatment, high-pressure water rinsing thoroughly removes loosened deposits and residual chemicals, leaving plates clean and fully functional.

- Reassemble the heat exchanger using new gaskets as needed.

- Conduct integrity and performance tests to confirm restored efficiency and operational readiness.

Nordic Green Products provides comprehensive cleaning services using the specially formulated cleaning agent NGP Valhall Fluid, ensuring optimal performance and extended operational lifespan of your heat exchanger systems.

- Evaluate fouling type and severity.

- Select appropriate method tailored to specific fouling conditions.

- Safely disassemble the PHE.

Inspect plates and gaskets for wear or damage.

- Perform chemical cleaning with NGP Valhall Fluid, a professional-grade, biodegradable cleaning solution designed specifically to remove:

- Rust and oxides

- Mineral scale (lime)

- Salts

- Algae and biological deposits

- Rust and oxides

Valhall Fluid is formulated with mild acids, providing a powerful yet safe cleaning action. It effectively dissolves deposits without damaging metal surfaces or components, although caution is required as it may corrode galvanized or zinc-treated surfaces.

- Following chemical treatment, high-pressure water rinsing thoroughly removes loosened deposits and residual chemicals, leaving plates clean and fully functional.

- Reassemble the heat exchanger using new gaskets as needed.

- Conduct integrity and performance tests to confirm restored efficiency and operational readiness.

Restoring Efficiency and Extending Equipment Lifespan

Plate heat exchangers (PHE) are vital for efficient heat transfer in industrial processes, yet they are vulnerable to fouling from minerals, biofilm, rust, salts, algae, and lime scale. Nordic Green Products provides comprehensive cleaning services using the specially formulated cleaning agent NGP Valhall Fluid, ensuring optimal performance and extended operational lifespan of your heat exchanger systems.

Our structured cleaning approach revitalizes heat transfer capacity, reduces downtime, and maintains high operational efficiency.

Benefits of Using NGP Valhall Fluid

- Non-toxic and biodegradable, ensuring environmentally responsible maintenance.

- Specialized formulation removes a wide range of deposits safely and efficiently.

- Minimizes equipment corrosion and damage compared to harsh acids.

- Improves heat transfer efficiency, directly reducing operational costs.

Advantages of Regular PHE Maintenance

- Enhanced thermal performance and energy efficiency

- Increased equipment reliability and reduced downtime

- Prolonged lifespan of heat exchanger plates and components

- Compliance with environmental regulations and sustainability standards

By choosing Nordic Green Products for your plate heat exchanger maintenance, you ensure that your equipment operates at peak performance, supporting the overall efficiency and reliability of your operations.