Weka Marine - Box Coolers

Weka Marine - Box Coolers

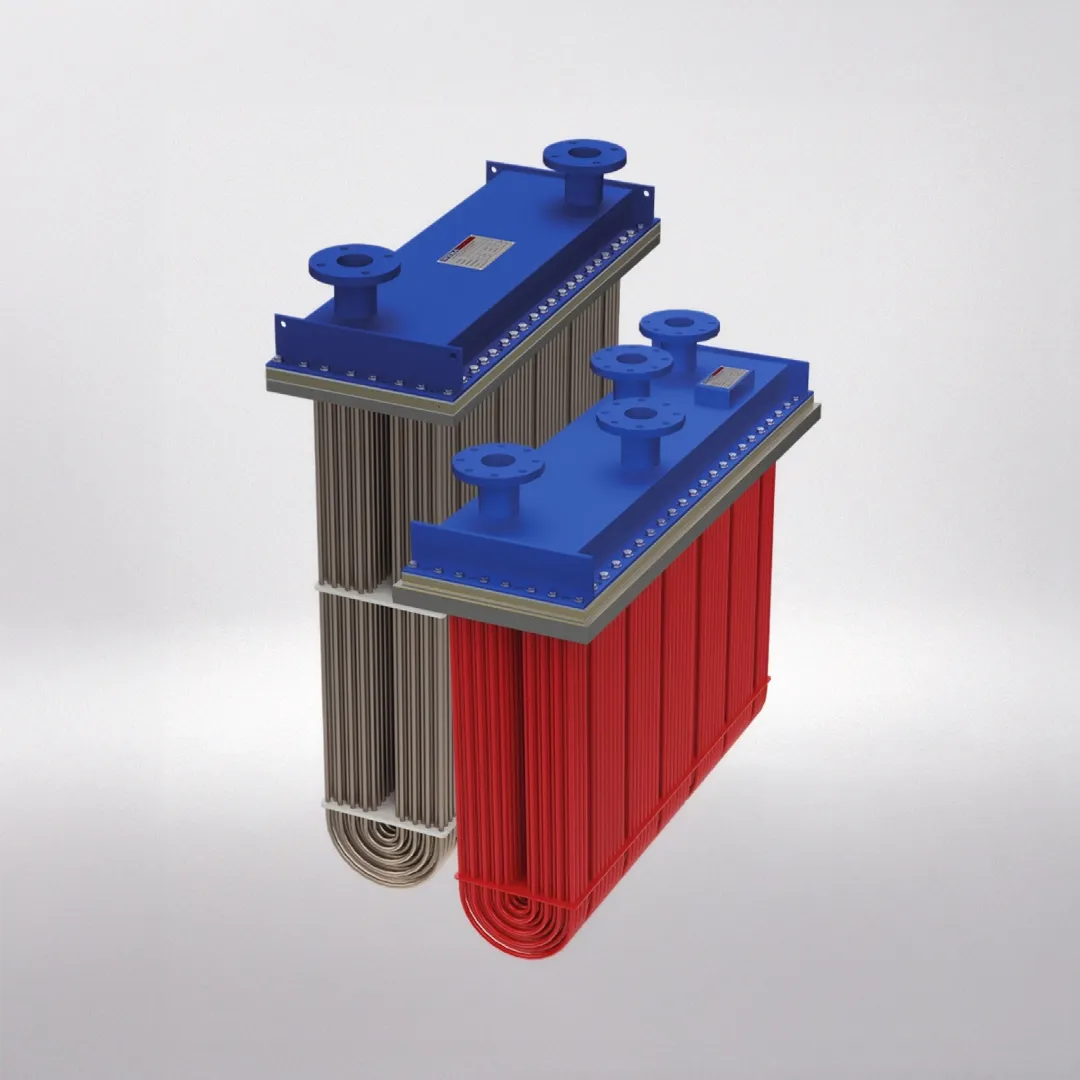

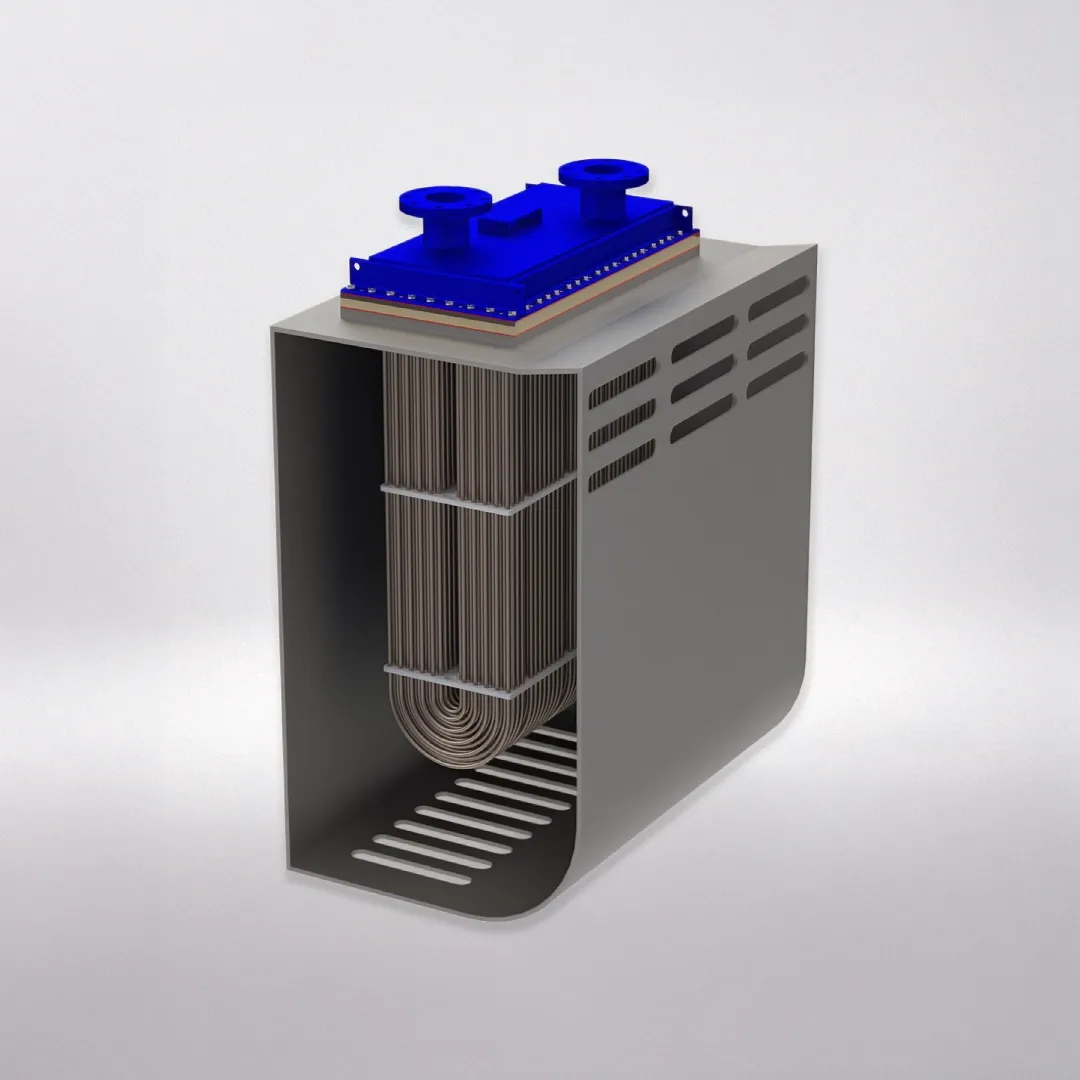

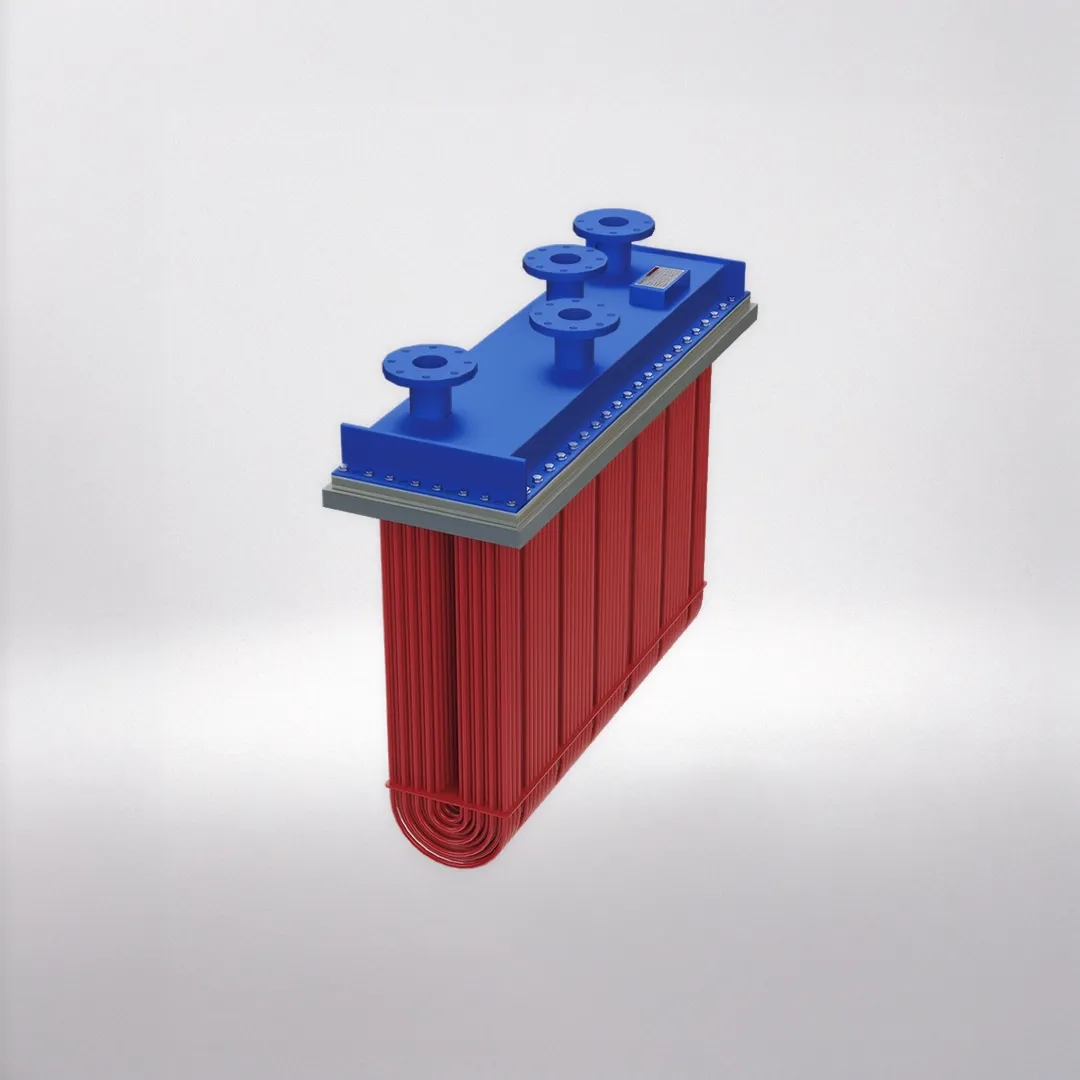

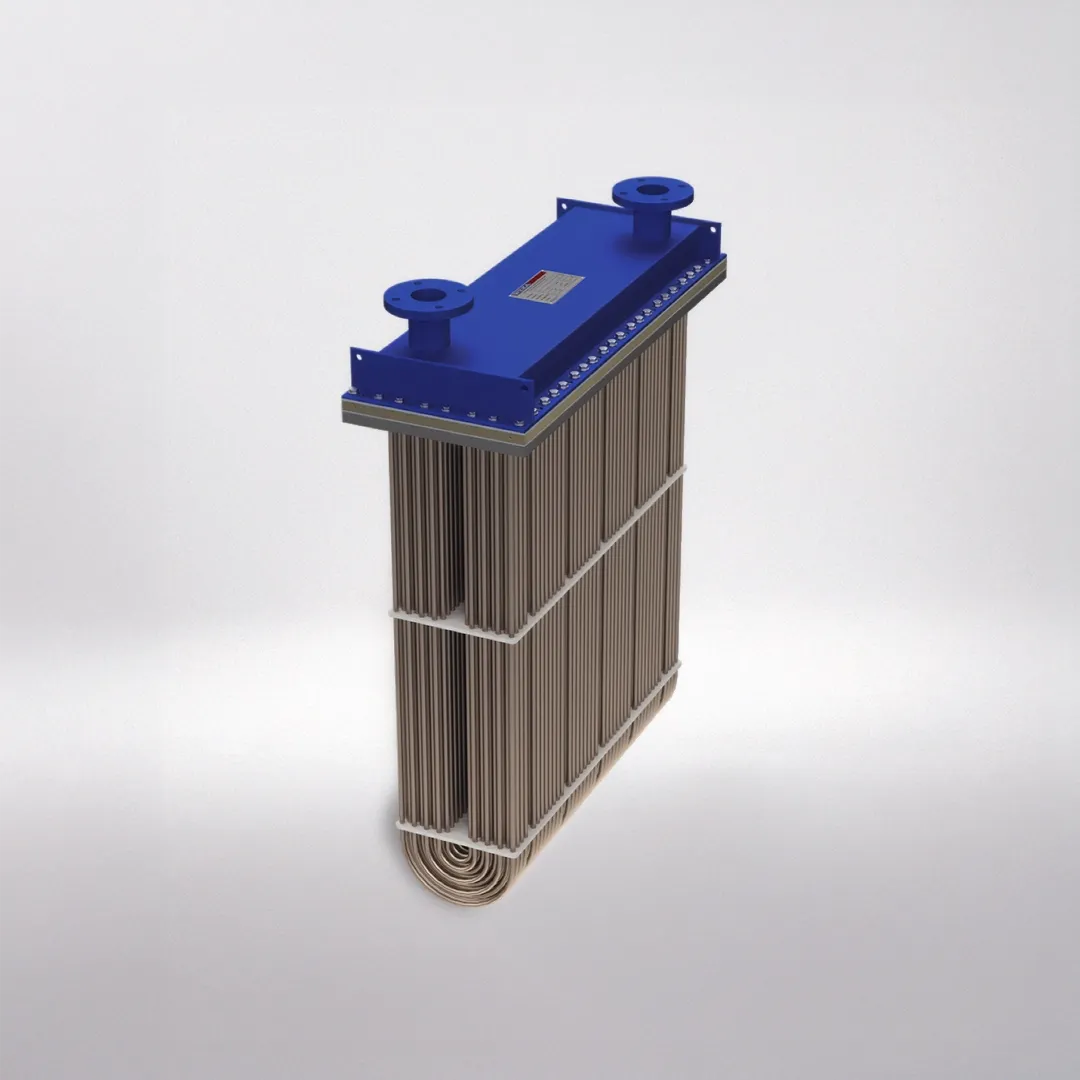

WEKA box coolers are compact and powerful, offering efficient engine cooling in a simple, space-saving design. Suitable for a wide range of vessel types.

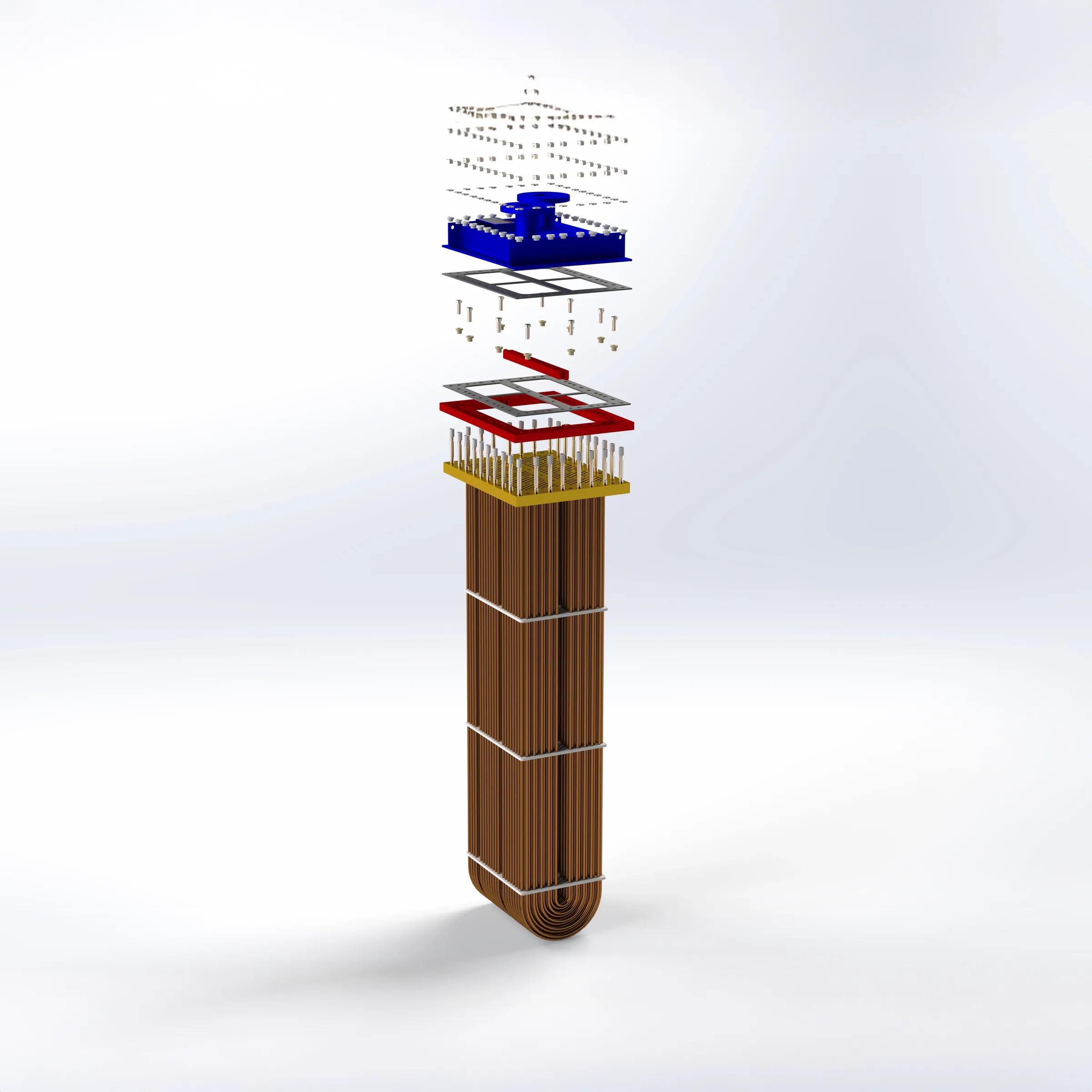

The aluminium brass box coolers are used throughout the marine market and are mainly selected for their strength. This alloy requires a protective phenolic, heat-cured coating and is combined with a protection system to ensure corrosion resistance against seawater and to prevent marine growth. Due to the coating, the box cooler is protected against galvanic corrosion while maintaining its high heat transfer capability.

Weka’s signature box cooler is constructed using uncoated 90/10 copper-nickel tubing. This alloy does not require a protective coating or ICAF (impressed Current Anti-Fouling) system due to its inherent corrosion resistance to seawater and natural anti-fouling capabilities. To protect the uncoated boxcoolers against potential stray current corrosion, a WEKA Guard™ and WEKA Protector™ system are applied. This exclusive design is successfully utilized in hundreds of vessels in fresh and saltwater applications worldwide.

Another copper-nickel cooling solution is the uncoated 70/30 copper-nickel box cooler. The 30% nickel alloy is stronger and can withstand higher seawater velocities, compared to the 90-10 alloy and does also not require a protective coating or ICAF (impressed Current Anti-Fouling) system due to its inherent corrosion resistance to seawater and natural anti-fouling capabilities.

To protect the uncoated box coolers against potential stray current corrosion, a WEKA Guard™ and WEKA Protector™ system are applied. This exclusive design is successfully utilized in specific cooling projects worldwide.

WEKA box coolers are compact and powerful, offering efficient engine cooling in a simple, space-saving design. Suitable for a wide range of vessel types.

The aluminium brass box coolers are used throughout the marine market and are mainly selected for their strength. This alloy requires a protective phenolic, heat-cured coating and is combined with a protection system to ensure corrosion resistance against seawater and to prevent marine growth. Due to the coating, the box cooler is protected against galvanic corrosion while maintaining its high heat transfer capability.

Weka’s signature box cooler is constructed using uncoated 90/10 copper-nickel tubing. This alloy does not require a protective coating or ICAF (impressed Current Anti-Fouling) system due to its inherent corrosion resistance to seawater and natural anti-fouling capabilities. To protect the uncoated boxcoolers against potential stray current corrosion, a WEKA Guard™ and WEKA Protector™ system are applied. This exclusive design is successfully utilized in hundreds of vessels in fresh and saltwater applications worldwide.

Another copper-nickel cooling solution is the uncoated 70/30 copper-nickel box cooler. The 30% nickel alloy is stronger and can withstand higher seawater velocities, compared to the 90-10 alloy and does also not require a protective coating or ICAF (impressed Current Anti-Fouling) system due to its inherent corrosion resistance to seawater and natural anti-fouling capabilities.

To protect the uncoated box coolers against potential stray current corrosion, a WEKA Guard™ and WEKA Protector™ system are applied. This exclusive design is successfully utilized in specific cooling projects worldwide.

Regulating air conditioning and hydraulic systems

WEKA Marine’s box coolers stand as the optimal choice for small and medium-sized vessels, encompassing a broad spectrum of vessels, including tugboats, barges, fishing boats, carriers, dredgers, supply vessels, ferries, icebreakers, cargo freighters, tankers, and reefers. Box coolers provide versatile temperature control solutions, serving various functions from cooling main engines, auxiliary engines, and bow thrusters to regulating air conditioning and hydraulic systems.

Our range of box coolers offers flexibility in terms of size, shape, and configuration to suit specific cooling capacity requirements. A prominent application for our box coolers involves efficiently dissipating waste heat generated by diesel engines and other heat sources like charge air coolers, lube oil coolers, and gear oil coolers.

WEKA Marine prides itself on the innovative technology that underpins our high-performance box coolers. Years of dedicated innovation and engineering excellence have led to the development of these top-tier solutions. This commitment drives our continuous efforts to enhance and optimize the mechanical design and thermal performance of our products, ensuring they meet the exacting demands of our valued customers, the evolving market, and classification societies across the globe.